Challenges and Solutions in Tablet Manufacturing: Ensuring Quality and Efficiency

Tablet manufacturing is one of the most critical processes in the pharmaceutical industry. Tablets are the most widely used dosage...

WERELDWIJDE VERZENDING - Bestel nu

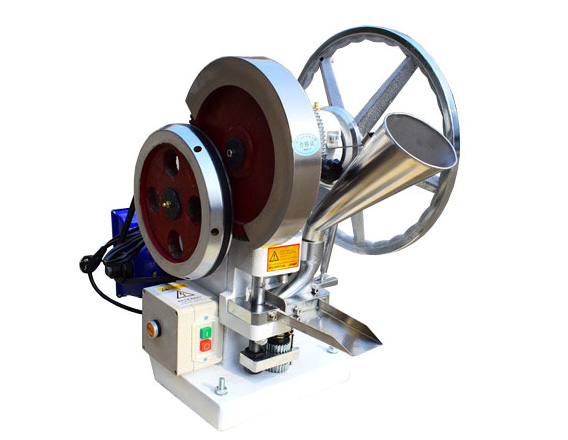

A tablet press machine, also known as a tablet compression machine, is a critical piece of equipment in various industries, especially pharmaceuticals. This guide provides an in-depth look at what a tablet press is, how it works, its types, components, historical development, trends, and its importance across different sectors.

A tablet press machine transforms powder into tablets of uniform size and weight using mechanical pressure. It offers the advantage of high-volume tablet production in a short span, making it essential for large-scale manufacturing.

The working principle of a tablet compression machine involves three key stages: filling, compression, and ejection.

In the filling stage, the machine's hopper dispenses a precise amount of powder into a die hole on a rotating turntable. The quantity of powder determines the tablet's weight.

During the compression stage, two punches compress the powder. The lower punch drops to accommodate the powder, then moves up to apply pressure while the upper punch completes the compression. The applied force determines the tablet's hardness.

After compression, the lower punch descends to allow the upper punch to withdraw. The lower punch then pushes the tablet out of the die, ready for discharge. The cycle then repeats.

Also known as an eccentric press, this machine is used for small-scale production, such as in laboratories. It produces one tablet per cam rotation and is valued for its flexibility and ease of operation.

Commonly used in the traditional Chinese medicine industry, this machine presses larger tablets, like compressed teas or herbal pills. It features high automation, structural stability, and high pressing pressure.

Ideal for large-scale production, rotary tablet presses have multiple stations that simultaneously fill, compress, and eject tablets. Their efficiency and ability to produce a variety of tablets make them suitable for mass production.

These components define the tablet's shape and size. By changing dies and punches, manufacturers can produce various tablet shapes and sizes.

This system ensures a consistent supply of powder to the tableting area, crucial for maintaining uniform tablet weight.

This system controls the pressure applied during compression, ensuring each tablet has consistent texture and hardness.

Responsible for removing tablets from the press, this device ensures smooth ejection and transport to packaging.

In rotary presses, the turntable supports punches and dies, facilitating multiple compressions for efficient production.

The motor drives the tablet press, powering the entire operation.

The journey of tablet presses dates back to the early 19th century, initially used for pressing hard candies. The early 20th century saw their adoption in pharmaceuticals, producing drugs like aspirin. By the late 20th century, advances in automation and productivity transformed tablet presses, making them integral to large-scale production. The 21st century brought further refinements, such as precise pressure control and advanced monitoring systems.

Modern tablet presses feature increased automation, improving efficiency and ensuring consistent quality.

Automated control and data acquisition systems enhance process and quality control, enabling better traceability and data management.

Tablet presses are becoming more adaptable to various tablet types and sizes, improving utilization and reducing production line switching costs.

New designs focus on energy efficiency and reducing environmental impact, aligning with stricter regulations and growing environmental awareness.

With the rise of precision medicine, tablet presses are adapting to small-batch, customized production needs.

Tablet presses are designed to meet diverse market standards and consumer needs worldwide.

Tablet presses are indispensable in pharmaceuticals, ensuring uniform weight and size for accurate dosage and efficacy.

They produce items like stock cubes and candies, enhancing packaging ease, shelf life, and consumer convenience.

Tablet presses enable large-scale production of supplements, ensuring precise dosage and meeting consumer demand.

They are used for producing everyday items like cleaning agents and personal hygiene products.

Tablet presses ensure accurate dosing in veterinary drugs, aiding in animal health.

Tablet press machines are vital across multiple industries, particularly pharmaceuticals. Their evolution over the years has enhanced their efficiency, versatility, and automation. As these industries expand, the demand for advanced tablet presses will continue to grow, shaping the future of manufacturing.

Interested in learning more about tablet presses? Contact us for detailed information, product demonstrations, and exclusive offers to enhance your production capabilities with our state-of-the-art equipment and expert support!

Tablet manufacturing is one of the most critical processes in the pharmaceutical industry. Tablets are the most widely used dosage...

Tablet compression technology has evolved significantly over the years, driven by the need for more efficient, precise, and versatile solutions...

Tablet press machines, often referred to as tablet compression machines, are essential tools in the pharmaceutical industry. These machines are...

Tablet compression machines, also known as tablet presses, are the backbone of tablet manufacturing in the pharmaceutical industry. These machines...