Home

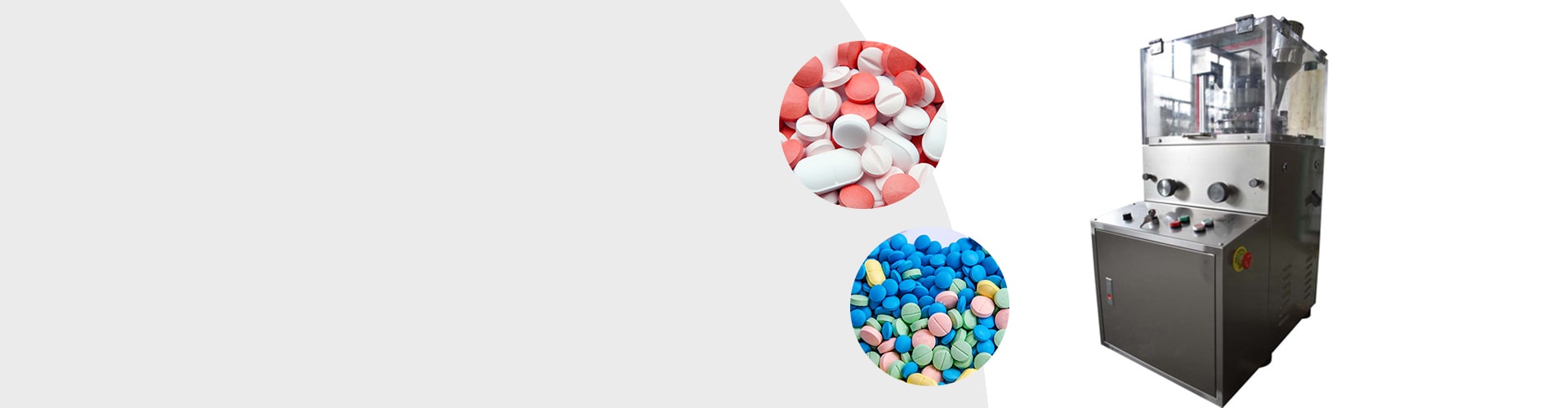

Buy tablet machines at the best prices with worldwide shipping

Looking for high quality tablet machines at the best prices with worldwide shipping? Look no further! Our company specializes in supplying top class tablet machines that meet the requirements of the pharmaceutical, nutraceutical and chemical industries.

Why should you choose us?

- First-class quality: Our tablet machines are manufactured using state-of-the-art technology and in compliance with strict quality standards to ensure reliability and durability.

- Wide range: We offer a wide range of tablet machines for different production capacities and requirements, from small to large operations.

- Competitive prices: We know how important cost efficiency is to your business. That's why we offer competitive prices without compromising on quality.

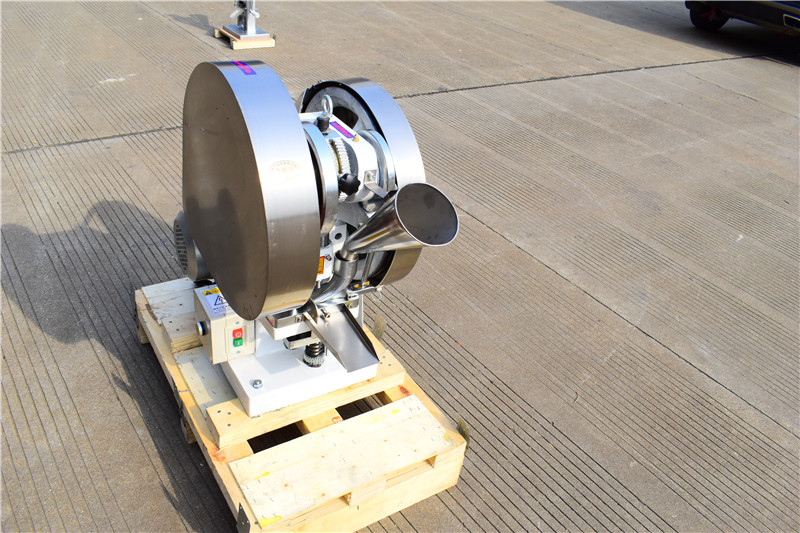

- Worldwide shipping: No matter where you are, we can deliver our products to you. With our efficient shipping partners, you can expect on-time delivery to your doorstep.

- Expert support: Our team of experienced professionals is committed to providing you with outstanding customer service. Whether you need help choosing the right machine or technical support, we are here for you.

- Customized solutions: We know that every company is unique. That's why we offer customized solutions that are tailored to your specific needs. Our experts will work closely with you to develop the perfect solution for your production requirements.

Don't settle for anything less than the best when it comes to your Tablet production goes. Contact us today to get a quote and take your production to the next level!

Advantages of ordering tablet presses in our store

Discover the numerous benefits you can enjoy when buying tablet presses in our store:

- High-quality selection: In our range you will only find high-quality tablet presses from renowned manufacturers to ensure you achieve first-class results.

- Wide range of models: We offer a wide range of tablet presses that cover different requirements and production capacities. Find the model that perfectly suits your needs.

- Transparent information: All product information, including technical specifications and features, is presented in a clear and understandable way to help you make an informed decision.

- Competitive prices: Benefit from fair and competitive prices that offer excellent value for money.

- Customer reviews: Read other customers' experiences with our tablet presses for additional information on product performance and reliability.

- Our online store offers a secure and user-friendly platform for your purchase. Your data is treated confidentially and we use the latest security standards.

- Fast shipping: We ensure that your order is processed and shipped quickly so that you can start using your tablet press as soon as possible.

- Customer service: Our dedicated customer service team is available to answer your questions and support you before, during and after your purchase.

- Guarantee and warranty: Enjoy the confidence in our products through comprehensive guarantee and warranty conditions that give you security and confidence.

- Customer orientation: Our focus is on the customer. We strive to exceed your expectations and offer you the best possible shopping experience.

Order your tablet press from our store today and benefit from these advantages for smooth and successful production.

Tablet press | Overview

Depending on the requirements in the specific case, very different types of tablet presses are available in the commercial sector. They differ mainly in their performance and in the quantity of tablets produced by the machine per specified unit of time. The following performance characteristics must be taken into account:

Interested? Take a look at our products!

Do you have any questions?

Eine Tablettenpresse kommt immer dort zum Einsatz, wo Pulver zu Tabletten komprimiert werden soll. In der Regel handelt es sich dabei um pharmazeutische Produkte.

However, not only medicines, but also lifestyle products, dietary supplements and cosmetics can be turned into products for retailers and end consumers in a tablet press.

The advantage of a tablet press is obvious: it guarantees that the tablets produced are uniform in size, shape and also weight - especially the last point is of paramount importance when it comes to the production of tablets for medical use.

When using a tablet press, the starting product is always a powder - and this is completely independent of the final product in which it is to be used afterwards. The powder can consist of various substances. These depend on the objective that will be pursued in the use of the future tablets. In addition to active substances, of course, excipients are also added to the powder - for example, colorants, but also binders and similar excipients.

The ready mixed powder is then filled into the tablet press. Depending on the size of the tablet press, the capacity of the machine is also aligned. This means: The larger the machine, the more powder can be filled - and the more tablets can be produced in one operation. The powder is then fed via a hopper into a die, which is fitted with punches from above and below and then presses the powder into the desired shape. The result is a finished and durable tablet that is also ready for further processing or packaging.

Tablets produced with a tablet press usually consist of granular starting material. The finer and more powdery the powder, the more concentrated the end product. However, not every tablet is also intended for use with superfine powder - here it is worth taking a look at the specific requirements of the machine. Only professional use guarantees a satisfactory result for manufacturers and also for consumers.

Moist starting materials cannot be used either. Here, too, the use and permissibility of the moisture contained depends on the specific tablet press.

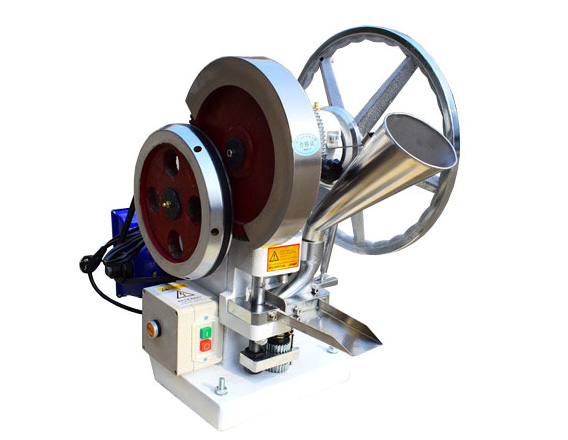

In the context of flexible use of the tablet press, another aspect is of concern to manufacturers and producers: not all tablet presses allow the choice between purely mechanical manual operation and electrical operation in the context of large-scale production. In the case of a flexible tablet press, this can certainly be set on a case-by-case basis - so production can be customized and individually adapted at any time without causing production downtime and unnecessary costs.

The tablet press, especially the devices in industrial use, regularly consist of the same components. These include, on the one hand, the filling chamber for the ready-mixed powder, already mentioned above, the hopper through which the powder is filled into the die and brought "into shape" with the punches.

This covers the essential components of a tablet press - both for tablet presses that are operated mechanically or with muscle power and for tablet presses that are operated with an electric motor. These are usually the devices that can produce large quantities of tablets and therefore dispense with purely manual operation.