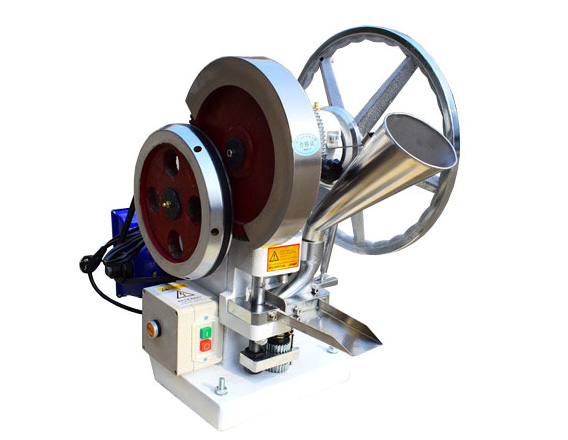

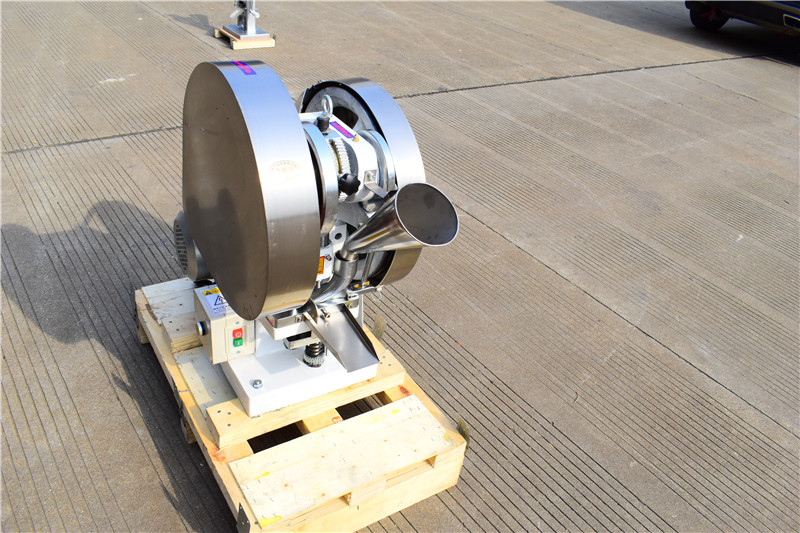

ZP-10B Rotary Tablet Press

5.999,00 €

Die ZP-10/12B Rotary Tablet Press ist – wie es der Name bereits indiziert – eine leistungsstarke Rundläufer-Tablettenpresse, die es dem Anwender ermöglicht, schnell und effizient große Mengen qualitativ hochwertiger Tabletten zu produzieren.

Advanced features of the ZP-10/12B Rotary Tablet Press include a digital interface and an extremely convenient operator console. Together, they make it easy for the operator to operate the machine without having to make time-consuming and cumbersome manual adjustments to bolts and screws.

Abholung in Deutschland ist nach Vereinbarung möglich und gegen einen Aufpreis kann ich die Maschine zu Ihnen nach Hause bringen, mit Nachnahme. Kontaktieren Sie uns gern unter der Rufnummer +49 (0) 160 979 116 53 by phone call or WhatsApp.

You can pick up the press in our stock house in Germany, besides, we can also deliver the press to your company or home in all EU countries using cash on delivery. Please feel free to contact with uns under the number +49(0)160 979 116 53 via WhatsApp or make a phone call.

- Frequently asked questions

- Technical data

What kind of material is the ZP-10/12B Rotary Tablet Press suitable for?

As with any other tablet press, it is recommended to use a particle size of approximately 80 to 60 mesh for the ZP-10/12B Rotary Tablet Press. Mesh is the unit that indicates the fineness of the fabric and always appears when it comes to the particle size of screened material. The particle size is also often of decisive importance when using tablet presses, because: Not all presses are designed, for example, to also process coarse-grained materials.

However, it is clear that if the powder is too fine and does not correspond to the specified mesh number, it is quickly lost in the manufacturing process. For the producer, this means - depending on the production quantity - a high loss of resources and also money. When using a tablet press, make sure that it is suitable for the powder used, in order to avoid large losses of any kind.

Whereas with a powder that is too fine, the loss in the manufacturing process is an important factor, with a material that is too coarse, the risk of operational disturbances is almost pre-programmed, because: The large particles can only be processed very poorly by the machine and basically always offer the risk of malfunctions in the processes.

Is the ZP-10/12B Rotary Tablet Press also suitable for beginners in tablet production?

From experience, the ZP-10/12B Rotary Tablet Press is somewhat easier to use than comparable tablet presses in the size range. This is because the ZP-10/12B Rotary Tablet Press has only one side that needs to be adjusted to your needs. Therefore, the ZP-10/12B Rotary Tablet Press is not blanketly more or less suitable for beginners in tablet production than other machines. The main problem that beginners often have when using tablet presses is the perfect composition of the tablets produced, and therefore the formula or recipe that forms the basis for production. Of course, this is always the case when a tablet press is used for the first time. Here, however, experience shows that with increasing duration of use, safety in use also increases - experienced users can unerringly produce even large quantities of tablets here without major losses.

By the way, the ZP-10/12B Rotary Tablet Press is particularly suitable for users who are primarily interested in producing large batches. For smaller quantities, other tablet presses are available that are much better suited to producing a manageable amount of tablets - after all, the ZP-10/12B Rotary Tablet Press can produce up to 20,000 tablets per hour, making it one of the most powerful tablet presses on the market.

| Model | ZP-10B | ZP-12B |

| Max. Pressure | 50 KN | |

| Max. Tablet diameter | 18 | 12mm |

| Max. Filling depth | 15 mm | |

| Max. Thickness of the tablet | 6 mm | |

| Production capacity | 30 r/min | |

| Production capacity (pc/h) | 18000 | 28000 |

| Power | 2.5kw | |

| Size | 810*810*1250mm | |

| Weight | 320 kg | |